Add to Cart

216 G657A1 Air Blown Fibre Microduct Air Blown Micro Cable GCYF4-216 Air Blown Cabling

Description

Benefits of air blown cabling

Air blown fiber optic cabling is a rising cabling technology that offers certain advantages over the traditional cabling method.

Space – Air blown fiber cabling technology uses less space than the traditional method, roughly one-sixth. The micro trench can fit more cables in less space than the traditional cabling method.

Scalable – once the backbone of conduits and pathways are complete, you can easily blow fiber through the pipe saving the cost of new installations. Upgrading of network or network wirings becomes easy and at a lower cost when the need arises. This can be done without necessarily disrupting your network services causing zero downtime if done correctly.

Less labour/manpower – fiber optic cabling using the air blown method uses less labour and manpower power compared to other methods. The cost of material might reduce as well with the use of an inner protective duct not necessary in most cases.

Reduces interconnections – air blown fiber cabling reduces interconnection points and splicing within the fiber line.

Technical specification

| P/N | GCYF4-216 | |

| Fibre count | 216 | |

| Loose tube count | 6+12 | |

| Filler count | 0 | |

| Fiber per tube | 12 | |

| Water blocking method | FRP or PE Lining | Water Blocking yarn |

| Cable Core | Water Blocking Kevlar | |

| Thickness of nylon jacket | Nominal: 0.45mm, Average: 0.40mm, Minimum: 0.35mm | |

| Nominal Diameter | 7.8±0.2 mm | |

| Weight | 55kg/km | |

| Max. Tensile Strength | 500N | |

| Max. Crushing Resistance | 800N/100mm | |

Fiber specification

| Single mode fiber | 9/125um OS2 G.657A1 |

| Chromatic dispersion | |

| @1285-1330nm ps/(nm.km) | - |

| @1550nm ps/(nm.km) | - |

| Attenuation - cable | |

| Max. @1310nm (dB/km) | 0.35 |

| Max. @1550nm (dB/km) | 0.24 |

| Max. @1625nm (dB/km) | 0.26 |

| Cable cut-off wavelength (λcc) (um) | ≤1260 |

| Mode field diameter | |

| @1310nm (um) | 8.6-9.3 |

| @1550nm (um) | 9.5-10.5 |

| Cladding diameter | 125.0±0.7 |

| Clad non-circularity | ≤1% |

| Coating diamter (um) | 235-245 |

| Core/clad concentricity error (um) | ≤0.5 |

| Coating/clad concentricity error (um) | ≤12 |

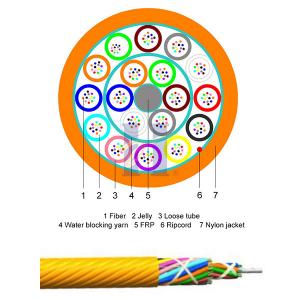

Cable structure:

Standard drum length

2000m/drum, 4000m/drum & 6000m/drum

Fiber color

| Fibre 1: Blue |

| Fibre 2: Orange |

| Fibre 3: Green |

| Fibre 4: Brown |

| Fibre 5: Grey |

| Fibre 6: White |

| Fibre 7: Red |

| Fibre 8: Black |

| Fibre 9: Yellow |

| Fibre 10: Violet |

| Fibre 11: Pink |

| Fibre 12: Aqua |

Loose tube color

| Loose tube 1: Blue | Loose tube 13: Blue |

| Loose tube 2: Orange | Loose tube 14: Orange |

| Loose tube 3: Green | Loose tube 15: Green |

| Loose tube 4: Brown | Loose tube 16: Brown |

| Loose tube 5: Grey | Loose tube 17: Grey |

| Loose tube 6: White | Loose tube 18: White |

| Loose tube 7: Red | |

| Loose tube 8: Black | |

| Loose tube 9: Yellow | |

| Loose tube 10: Violet | |

| Loose tube 11: Pink | |

| Loose tube 12: Aqua |

Cable text print: (Support customized text)

HYOC GCYFT4 216 G657A1 [Drum No.] [Month-Year] [Meter marking]

Order information

| Fiber count | Fiber class | P/N |

| 216 | G657A1 | MICRO 18X12F G657A1 PA 7.8MM |

| 216 | G652D | MICRO 18X12F G652D PA 7.8MM |

| 216 | OM1 | MICRO 18X12F OM1 PA 7.8MM |

| 216 | OM2 | MICRO 18X12F OM2 PA 7.8MM |

| 216 | OM3 | MICRO 18X12F OM3 PA 7.8MM |

| 216 | OM4 | MICRO 18X12F OM4 PA 7.8MM |

Factory & office

Production line